Carbon Fiber Reinforced Composites Have Which of the Following Properties

Effect of the Concentration of the Sizing Agent on the Carbon Fibers Surface and Interface Properties of Its Composites R. Very high modulus of elasticity exceeding that of steel.

Learning Center What Are Unidirectional Carbon Fiber Fabrics

It is also seven times stronger two times stiffer and 15 times lighter than 6061 aluminum.

. FIBER REINFORCED POLYMER COMPOSITE Fiber composites may be classified according to the nature of the matrix and the fiber. Carbon fiber reinforced PEEK OptimaA composite material biomechanical properties and weardebris characteristics of CF-PEEK composites for orthopedic trauma implants. Have different values parallel to the fiber from those perpendicular to the fiber or layer Excellent resistance to alternating loads even at relatively high tem-peratures Pseudoplastic fracture behavior Corrosion resistance and resistance to radiation Production of high-purity grades possible Characteristic properties.

Carbon fiber-reinforced silicon carbide is applied for aircraft brakes to withstand temperatures up to 1200 C. Prevents the fibers from environmental attacks such as chemicals and mechanical degradation of the surface of the fibers. The required directional properties can be achieved in the case of fiber reinforced composites by properly selecting fiber.

Offers certain properties like ductility toughness and. Generally composite materials are classified and related to constituents as shown in figure 1. Carbon fiber reinforced composites are five times lighter than grade 1020 steel as well as five times stronger.

Carbon fiber reinforced polymer composites CFRP have several excellent properties. Carbon fibers are used for reinforcing polymer matrix due to the following their properties. Aligned The properties of aligned fiber-reinforced composite materials are highly anisotropic.

Four-point bending bridge distances were set Five samples of the Piccolo composite DCP that were 45 mm following the requirements of ASTM F382 based on plate in thickness. True Which of the following is a drawback to superconductors. Using CFRPs instead of aluminum can reduce 40 of mass while having the same mechanical properties 4 10 41424344.

Hybrid kenafglass fiber-reinforced polymer composites showed enhanced mechanical properties with rain erosion resistance suitable for aircraft application. Composite Materials Classification 10 11. The longitudinal tensile strength will be high whereas the transverse tensile strength can be much less than even the matrix tensile strength.

The main objective of this work is to investigate the degradation of Carbon-Fiber-Reinforced Polymers CFRP composites under different atmospheric conditions and its influence on the tensile strength. Su2 1 School of Materials Science and Engineering Shandong University of Science and Technology 266510 Qingdao Peoples Republic of China 2 School of Chemical Engineering and Technology State. The matrix has the following role in fiber reinforced composite materials.

Carbon fiber-reinforced plastic composites have been intensively used for many applications due to their attractive properties. The motivation is primarily for lightning strike protection. Fiber reinforced composites can be a tailor made as their properties can be controlled by the appropriate selection of the substrata parameters such as fiber orientation volume fraction fiber spacing and layer sequence.

The increasing demand of carbon fiber-reinforced plastic composites is driving novel manufacturing processes to be in short manufacturing cycle time and low production cost which is difficult to realize during carbon fiber-reinforced plastic. Composites such as carbon-fiber-reinforced polymers have the properties of both metals and plastics. Holds the fibers together.

Studies have shown that adding a basalt fiber layer BF to CFRP materials can improve its extensibility 2 3 making the basalt fibercarbon fiber hybrid. Some common geometries for fiber-reinforced composites. Carbon fiber reinforced polymer CFRP composites offer greater stiffness and strength than any other type but they are considerably more expensive than glass fiber reinforced polymer GFRP.

Pore size was varied from monomodal to multimodal distribution with the addition of carbon fibers. Transfers load and stresses between the fibers. 2016 365 157168 DOI.

Mahat Ibrahim Alarifi Abdulaziz Alharbi Ramazan Asmatulu Summary. The recent attention in the applications of the fiber reinforced thermoplastic composite have raised some concerns. It will depend on the properties of the fibers and the matrix the interfacial bond.

The increase of carbon fiber content has increased the porosity of the composites. 4 rows Carbon-carbon composites present a family of materials composed of carbon fiber reinforced. Up to 10 cash back Conductive nanofillers such as carbon nanotube graphene nanoplatelets and carbon black particles with diameters in nanometers have been shown to enhance the electrical conductivity of fiber reinforced polymer matrix composites in many existing studies.

High tensile strength which may reach 1000 ksi 7 GPa. 101002masy201650015 157 Effects of UV Light on Mechanical Properties of Carbon Fiber Reinforced PPS Thermoplastic Composites Khairul B. Up to 10 cash back Carbon-fiber-reinforced plastic CFRP is widely used in the aerospace weapons and automobile industries as well as in other fields but its poor ductility limits its further development 1.

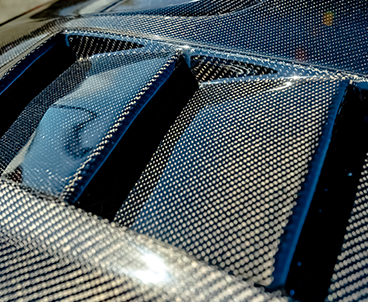

Carbon Fiber-reinforced polymers carbon-fibre-reinforced polymers or carbon-fiber-reinforced plastics or carbon-fiber reinforced-thermoplastic are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce but are commonly used wherever high strength-to-weight ratio and stiffness are required such as aerospace. The carbon fiber reinforced metal matrix composites provide excellent strength and mechanical performance ease of manufacturing technique excellent thermal and electrical properties enhanced wearcorrosion resistance and reduced coefficient of friction making CF-MMCs appropriate for a variety of engineering applications.

Short carbon fiber reinforced silicon nitride composites were fabricated by reaction bonding method. Good chemical resistance outstanding mechanical properties at low density and strength characteristics can be tailor-made for a given load. Continuous fibers in a polyester or epoxy matrix give the highest performance.

What Is Carbon Fiber Dragonplate

Carbon Fiber Composites Properties Manufacturing Methods Pros And Cons

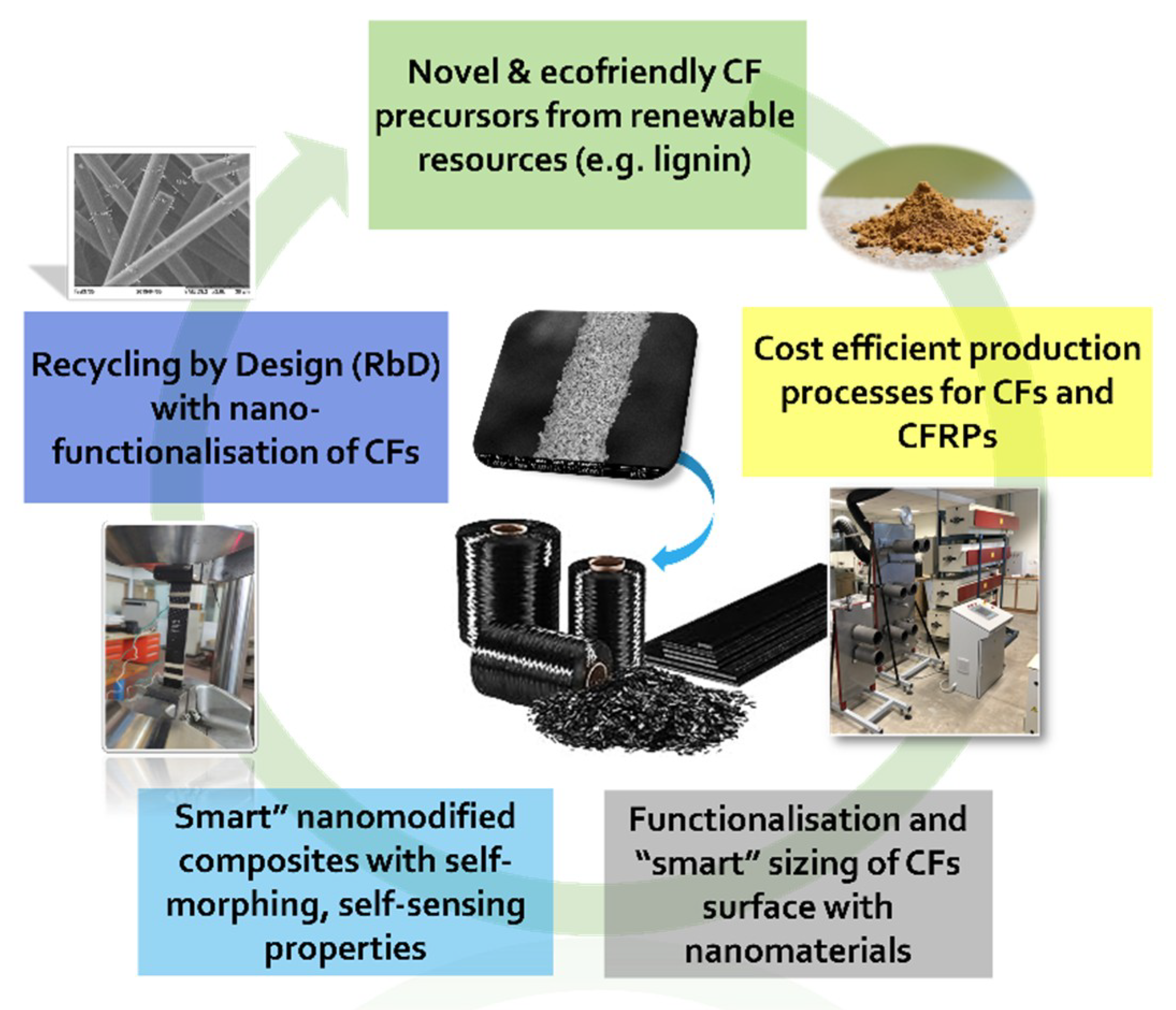

J Compos Sci Free Full Text Research And Development In Carbon Fibers And Advanced High Performance Composites Supply Chain In Europe A Roadmap For Challenges And The Industrial Uptake Html

Carbon Fibre Reinforced Polymer An Overview Sciencedirect Topics

Carbon Fiber Dupont Kevlar And Fiberglass Fibre Glast

Carbon Fiber Composites Properties Manufacturing Methods Pros And Cons

Nanotube Carbon Fiber Overview The World Of Nanoscience

Carbon Fiber Vs Fiberglass Tubing Which Is Better

Carbon Fiber Composites Properties Manufacturing Methods Pros And Cons

Polymers Free Full Text Carbon Fiber Reinforced Polymer For Cable Structures A Review Html

Ultimate Guide To Carbon Fiber Design Application

Carbon Fiber Vs Steel Element 6 Composites

Ultimate Guide To Carbon Fiber Design Application

Carbon Fiber Dupont Kevlar And Fiberglass Fibre Glast

Making Load Carrying Fibre Composite Structures More Accessible Materials And Engineering Resources Matmatch

What Is A Composite Material A Definitive Guide Twi

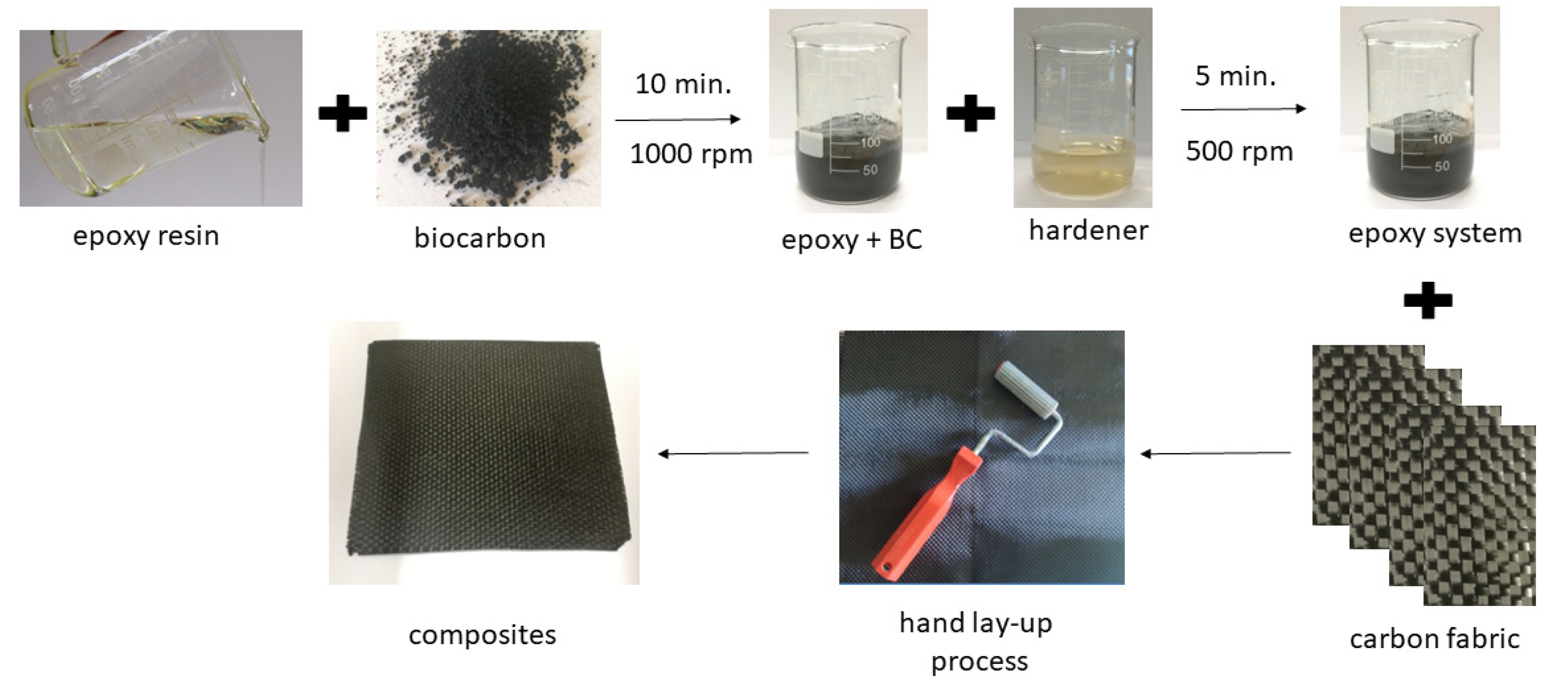

Processes Free Full Text Biochar As An Effective Filler Of Carbon Fiber Reinforced Bio Epoxy Composites Html

Understanding The Potential Of Carbon Fiber Composites For Automobiles Research Development World

Comments

Post a Comment